In Hospitals, Backup Power Is Life Support

Ensure That Fuel Is NEVER Your Weak Link

On paper, fuel is just another line item. In reality, it’s the difference between reliable emergency power and catastrophic failure.

Is Backup Fuel Your Weak Link?

When the grid drops, hospitals must transfer to emergency power within seconds. If the generator hesitates or fails to start, patient care stops instantly.

This isn’t just downtime - it’s a life safety event, and accountability is immediate.

What’s at risk in a real outage:

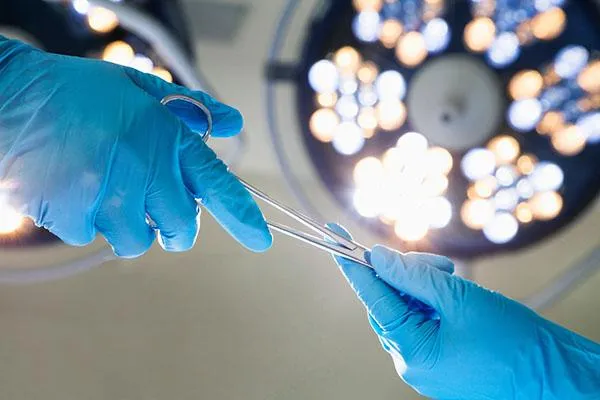

Operating rooms go dark mid-surgery.

ICU ventilators and monitors shut down.

NICU warmers and life support equipment lose power.

Emergency departments, cath labs, and imaging suites stall.

Infusion pumps, dialysis treatments, and oxygen concentrators stop.

Negative-pressure rooms lose containment.

Elevators freeze with patients and staff inside.

Nurse call systems and electronic health records go offline.

Pharmacy automation and lab analyzers stop

When the lights go out, the hospital’s reputation and patient trust are on the line as much as life safety. Protecting both means ensuring fuel never becomes the hidden reason emergency power fails.

Hospitals don’t just face hypothetical risks...

Generator failures have had real and devastating impacts on patients and staff:

Intermountain Medical Center (Utah, Aug 2025): Generator failure during an outage forced ambulance diversions, including transfers of five NICU babies and six mothers.

Thibodaux Regional Health System (Louisiana, Aug 2021, Hurricane Ida): A partial generator failure left ICU staff hand-ventilating patients until transfers could be arranged.

Ryder Memorial Hospital (Puerto Rico, Oct 2017, Hurricane Maria): Generator failure required five ICU patients to be airlifted to the USNS Comfort hospital ship.

Hospital Menonita de Caguas (Puerto Rico, Oct 2017, Hurricane Maria): Generator failure forced evacuation of four ICU patients by helicopter to the USNS Comfort.

These events underline a simple truth: when emergency power fails in a hospital, everything fails with it.

Engines are tested. Switchgear is tested. But the fuel - the one component expected to sit in storage for months or years - is too often ignored.

Over time, stored diesel breaks down:

Water condenses inside tanks.

Microbes multiply at the water–fuel interface.

Sludge forms, clogging filters and lines.

Injectors gum and performance drops.

A full tank is not the same as ready fuel. Hospitals need fuel that stays stable, clean, and reliable - every day of the year.

A full tank is not the same as ready fuel. Hospitals need fuel that stays stable, clean, and reliable - every day of the year.

If the emergency comes months after the last tank check, degraded fuel may be the reason the generator fails.

As fuel sits:

It ages and oxidizes.

Water accumulates through condensation.

Microbes multiply at the water–fuel interface.

Contaminants settle and form sludge.

Hospitals don’t just need tanks full of fuel. They need fuel that performs when called — no matter how long it has been in storage.

Hospitals rely on two outside partners:

Generator service companies to keep engines and switchgear ready.

Fuel polishers to clean tanks and remove sludge.

Both are essential. But neither can prevent re-contamination or instability without proper chemistry. Polishing may clean a hospital fuel storage tank today, but without treatment, the problem returns. A well-serviced generator still cannot run on degraded fuel.

Bell Performance provides the missing piece that keeps fuel stable, reliable, and ready — so your hospital is never caught unprepared.

For over 100 years, Bell Performance has specialized in one thing: fuel that performs when it matters most.

Our approach helps hospitals:

Stabilize fuel for long-term storage and readiness.

Control water and corrosion to protect tanks and keep filters clear.

Suppress microbial growth before it creates sludge and blockages.

Keep filters and injectors clean so generators not only start, but carry full load.

Integrate seamlessly with vendors or in-house teams so service and polishing deliver lasting results.

With Bell Performance in the tank, fuel stops being the weak link — and emergency power becomes a strength you can count on.

The cost of prevention is minimal compared to the cost of failure. When backup power falters, hospitals face:

Lawsuits, sentinel events, and public scrutiny from patient harm.

Immediate financial losses from suspended CMS or Medicaid reimbursements.

Lasting reputational damage that lingers long after the lights are back on.

One outage can cost more than years of proactive fuel management. The smartest business decision is the one that keeps patients safe, compliance intact, and your hospital’s reputation protected.

Critical facilities across the country rely on Bell Performance to keep stored fuel stable and generators ready. Our chemistry, backed by more than a century of field experience, gives your team and your vendors a repeatable way to pass audits and perform under load.

When patient lives, compliance, and reputation are on the line, trust the fuel that will not fail.

Protect patients. Protect compliance. Protect your reputation.

Spend 15 minutes with a Bell Fuel Chemistry Expert. No sales.

Just targeted advice to keep hospital backup fuel ready and to help service providers deliver lasting protection.

A full tank is not enough. Hospitals need fuel that STAYS READY.

Intermountain Medical Center (Murray, UT), Aug 14, 2025 – generator failed, cause undetermined; transfers included five NICU babies and six mothers ↩

Thibodaux Regional Health System (Thibodaux, LA), Aug 30, 2021 – partial generator failure during Hurricane Ida; ICU staff hand-ventilated patients; transfers arranged ↩

Ryder Memorial Hospital (Humacao, PR), Oct 4, 2017 – generator failed after Hurricane Maria; five ICU patients airlifted to USNS Comfort ↩

Hospital Menonita de Caguas (Caguas, PR), Oct 6, 2017 – generator failed after Hurricane Maria; four ICU patients evacuated to USNS Comfort ↩